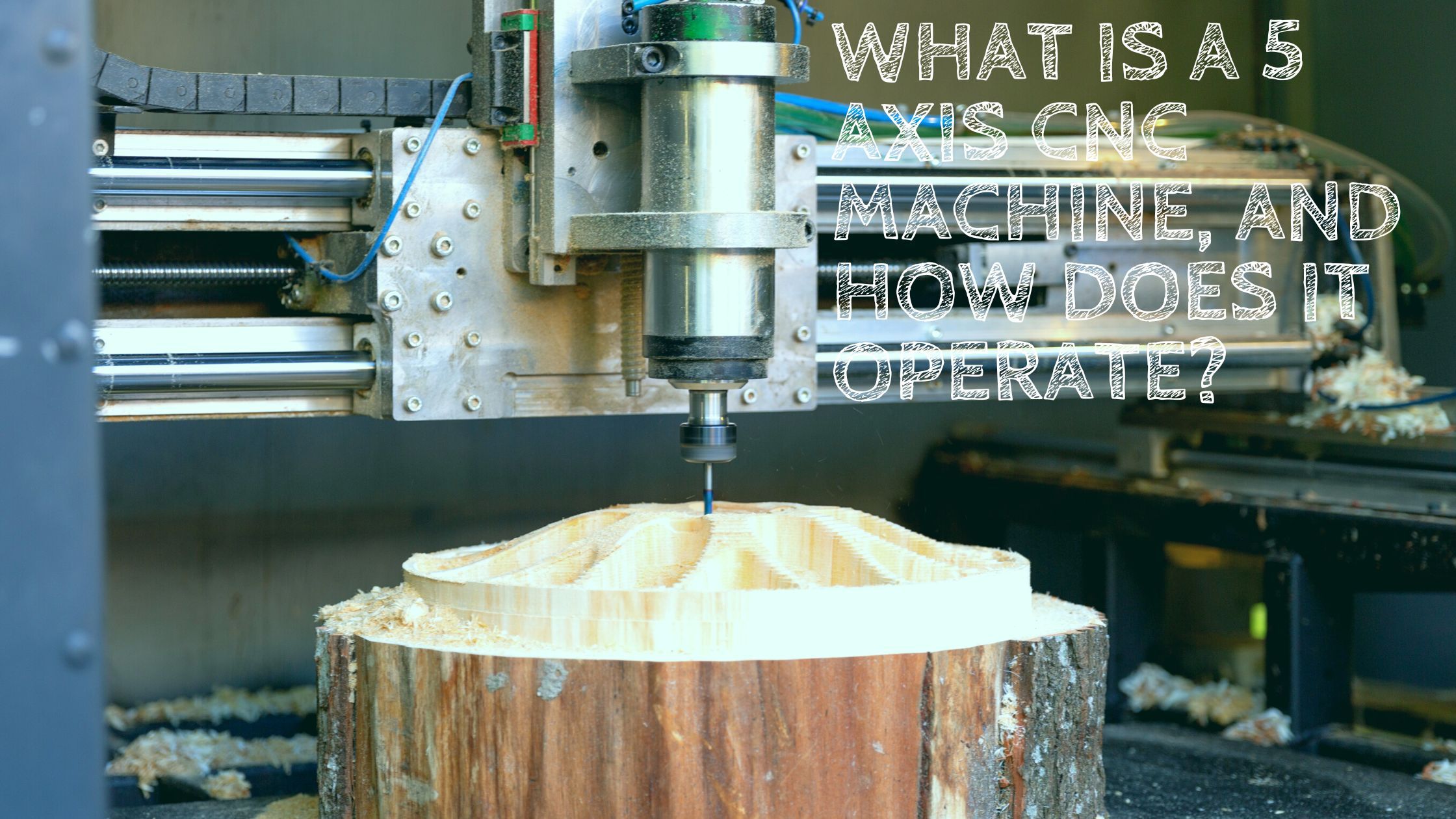

A 5-axis CNC router cutter is an exact machine that uses computer numerical control to machine various parts and assemblies. It has five axes (which means it can move in five directions simultaneously), making it ideal for welding, cutting, milling, and many other precision tasks.

This blog post will look at a 5-axis CNC router cutter and how it works. We'll also provide a few examples of its applications so that you have a better understanding of its potential benefits. A 5-axis CNC router cutter is a cutting and welding powerhouse. One of its key applications is in the manufacturing of aircraft parts. Using its five axes, it can carve out complicated shapes without any interference from other machines or humans. It's also incredibly accurate, meaning that even tiny mistakes can result in significant frustration (wasted time and money).

If you are finding a machine that can precisely handle complex projects, a 5-axis CNC router cutter is a perfect choice. This cutting machine is controlled by computer software, which allows for 3D modeling and editing of parts before they're cut out. This makes the machine perfect for woodworking and metalworking, where intricate cuts are required with high precision. Additionally, the engine uses five axes to create detailed cuts with high accuracy. If you are finding a machine that can handle various tasks, a 5-axis CNC router cutter is a great option to consider.

To operate a 5-axis CNC router cutter, you'll first need to download the necessary software. Once this is done, you can start editing your 3D models and creating precise cuts. To do this, you'll use the computer's mouse or keyboard to control the direction and movement of each of the five axes. This allows precise cutting in all orders without interference from other machines or humans. As mentioned earlier, a 5-axis CNC router cutter is perfect for tasks such as woodworking and metalworking, where intricate cuts are required with high precision. If you want to take your craftsmanship to the next level, a 5 axis CNC router cutter is an essential tool.

The 5-axis CNC router cutter is a modern innovation that traces its roots back to the 1950s. At this time, computers were relatively new and lacked the power to handle complex tasks. As a result, many traditional machines were replaced by5 axis CNC router cutters to create more accurate cuts. Today, these machines are still used extensively across many industries due to their precision and versatility. If you are finding a machine that can accurately handle complex projects, be sure to check out our selection of5 axis CNC router cutters.

Various configurations are possible for a 5-axis CNC router cutter. The most common configuration is known as the Cartesian coordinate system. In this system, each axis is represented by two numbers: X (left) and Y (right). To use this system, you'll need to first create your 3D models in CAD software and map them onto the X-Y plane. Next, you'll need to specify which axis corresponds to which direction on the screen. For example, if you're cutting along the x-axis, your computer will display instructions telling you how to move the machine's cutting tool along the y-axis. There are also other configurations available, such as the rotational coordinate system. In this system, each axis is represented by a number that cycles around 360 degrees. To use this system, you'll need to create your 3D models in CAD software and map them onto a unique 2D grid. Next, you'll enter the coordinates of where you want your model to start and finish on the grid. Finally, you'll specify which axis corresponds to which direction on the grid (e.g., X for left-handed users and Y for right-handed users).

One of the primary advantages of using a 5-axis CNC router cutter is its excellent precision. This is because each axis can be moved in precise increments, which allows you to make accurate cuts. In addition, 5-axis machines are also very versatile and can handle complex projects with ease. They're perfect for aerospace and automotive manufacturing industries, where accuracy and versatility are key factors. 5-axis CNC router cutters can also be used to generate 3D models. This is helpful in several ways: it allows you to create designs that are impossible or difficult to achieve using traditional methods, it can help you analyze and optimize your existing design, and it can enable you to test new concepts before actually bringing them into production.

Well, for one thing, it's incredibly fast. It can cut and weld parts at much faster speeds than traditional machines. This means that it can produce more complex parts more quickly, which in turn means less downtime and wasted resources. Additionally, its accuracy allows for exact cuts and welds - something that is essential in the aerospace industry. In fact, because of its precision and speed ratings, many experts believe that a 5 axis CNC router cutter will eventually outpace traditional machinery completely when it comes to high-quality manufacturing parts.

There are many other applications for a 5-axis CNC router cutter as well. Some of the most common include manufacturing robots, construction tools, and even car parts. It's also becoming increasingly popular in the automotive industry as it provides advantages over traditional methods like welding and machining. For example, using its five axes, a 5 axis CNC router cutter exporter can produce much tighter tolerances - especially important for vehicles with delicate internal mechanical components. Additionally, because it can cut and weld at such high speeds, a 5-axis CNC router cutter is perfect for cutting and welding light materials like aluminum.

If you're wondering what a 5 axis CNC router cutter is and how it works, you're in the right place! In this blog, we'll provide you with everything you need to know about 5 axis CNC router cutters, from their history to the different types of applications they can be used for. So, stay tuned for more information on this fascinating machine!